Technology & Quality

State-of-the-art technology, high degree of automation and a trained and motivated team are our guarantee of quality.

Our production process is fully automated. The operators prepare and calibrate the equipment between production runs and supervise the quality of the final product. We have a centralised system of automatic feed of raw materials, with PLASTIC SYSTEMS. equipment. We guarantee the automatic control of the main characteristics of the product at the exit of the machine (weight, watertightness, density) and its storage for shipping. Through robots of extraction and storage of bottles, we make the packaging at the exit of the machines. Through robotic film machines with rotary arm for palletising the finished product, we considerably improve the quality of the filming and the final result / presentation, without the risk of falling boxes / pallets. We recover and take advantage of surplus production processes in subsequent production series. The technology and quality of our production process guarantee the quality and reliability of our products.

Used materials

PET (Polyethylene Terephthalate), PE (High and Low Density Polyethylene) and PP (Polypropylene) are thermoplastic polymers which are mainly used in the textile industry and the manufacture of packaging.

Because they have thermoplastic properties, when heated to suitable temperatures, these plastics soften, melt and can be re-molded.

Providing an early response to European Community guidelines for the use of packaging made from recycled raw material, INDUMEL is prepared to produce Recycled PET packaging with Food Contact Certificate.

Technologies

INJECTION MOLDING

Production of lids for flasks, cups, spoons and other

INJECTION BLOW MOLDING

Production of jars, bottles and other types of hollow pieces (PET)

EXTRUSION – BLOW MOLDING

Production of bottles, bottles and other type of hollow pieces (PEHD / PP)

Quality

We have developed an integrated Quality System Management platform, supported by SAP, where we integrate and process the records obtained every hour regarding the creation of batches, definition of the parameters of each batch, internal record of anomalies or registration of external complaints, With access to the necessary product traceability data.

INDUMEL’s Quality Management System is certified according to the new ISO 9001: 2015 standard.

We carry out continuous professional training actions, in order to prepare employees and update them in current practices.

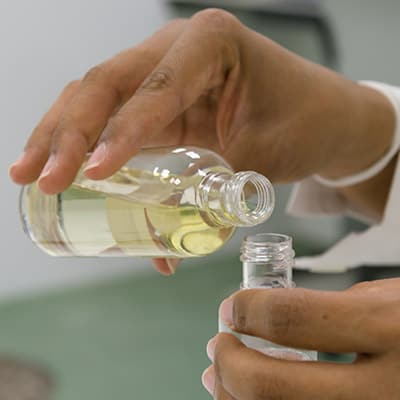

We have a quality control laboratory, where we carry out exhaustive tests on the product at the exit of production, namely in weight, size, opacity, porosity, sealing, edges, thickness of the walls of the packaging and load tests.

Innovation

INNOVATION – INDUMEL continuously researches the plastics and packaging production market, providing Customers with the latest solutions from the point of view of design, and existing technologies. With an internal team with many years of experience and technical skills, we use 3D modeling software (SOLID WORKS) and we provide our customers prototypes of new packages in real-size 3D printing. In this way, the Customer has the possibility to physically evaluate the best packaging solution for their product.

Universities and technical training

Because we believe that “knowledge” is obtained from all those who are involved in the activity of plastic transformation and packaging design, we actively participate in the relationship with the educational environment, whether through the frequency of Training courses and conferences promoted by these institutions, by the invitation of specialists to carry out training for our team and by the reception of young trainees or students with curricular works in our area.